Warehouse management logistics allows for a flexible customer's needs satisfaction by simultaneously reducing the stock and service costs.

Warehouse Management System is an IT tool used for supporting warehouse management, ranging from good reception, its localization and warehouse status check, to the release process. The goods in the warehouse are identified by a unique logistics unit code or by consignment number and other characteristics connected with a certain deployment, i.e. best-before date. The system offers warehouse outsourcing and the goods can be additionally identified by its owner's personal data. A peculiar task executed by the WMS is errorless goods localization in the warehouse and warehouse rotation process control. The system provides the information on the warehouse status based on various criteria and enables efficient localization of every single consignment and shipment. The WMS operator can generate a proper label and assign it to trade units during goods reception at the warehouse or introduce in the system the information included on the label previously assigned by another entity.

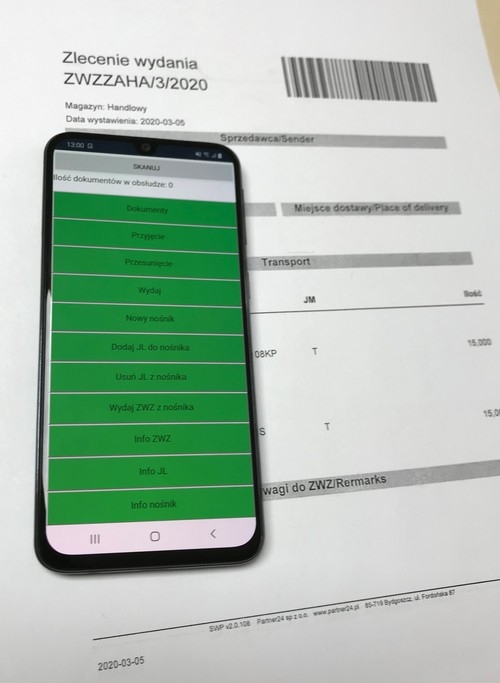

A string of actions is directly done by the staff. They are equipped with wireless data collectors featuring barcode or RFID label reading, which they use to confirm the executed operations. It allows the company to get the real-time image of warehouse status and enables an easy access to the full history of warehouse events. Our software cooperates with data collectors of well-known and reliable brands like Zebra and Datalogic and it can also be operated from Android mobile devices that use its camera as a barcode scanner.

WMS can be easily integrated with other business processes especially during sales, purchasing, and accounting. The software can also be an integral part of our EPR system. We deploy WMS all over the country.

Read more about WMS.

Reception

- external order reception support

- internal order reception support – the reception from production

- returnable packaging support

- goods layout management

- logistics unit template generation

- return and complaint support

- unloading support

- logistics data support

- DMS system and reception attachment support

- barcode-filled label printing

- photo-documentation

- entrusted goods support together with proper contractor assignment

- received goods fault registration

- goods, consignment, document marking according to the specification of the field which WMS is installed in

Releases

- external order release support

- internal order release support – the release to production

- returnable packaging support

- delivery route optimization

- loading management

- logistics data support

- DMS system and release attachment support

- photo-documentation

Picking

- picking order support

- picking order division for several areas

- returnable packaging support

- quick inventory

- task automation based on goods characteristics, consignment or documentation

- full inventory support

Logistics

- logistics contracts

- freight support

- mover support

- container support

- on-site mover management

- cost and profit calculation

Analytics and reporting

- respective operation time registration

- cost registration

- modified pivot table report generation

- predefined report generation in any form

- warehouse documentation automation

Benefits of implementing WMS

The implementation of the WMS warehouse program brings a number of benefits at the operational level of the company, visible after a few days of starting the system, which build the competitive advantage of the organization. The most important advantages of implementing a warehouse program include:

- Reduction of warehouse maintenance costs by reducing the time of warehouse operations. Operators perform tasks defined in the system, and the software optimizes the steps necessary to perform them, so that warehousekeepers achieve their goals with less effort, and the warehouse space itself is used optimally.

- Always real stock. All warehouse operations are carried out on an ongoing basis using data collectors with barcode readers, which reflects the real inventory at the given moment in the IT system. The use of bar codes to operate the warehouse streamlines work while minimizing the number of mistakes.

- Analysis of bottlenecks. The use of the integrated WMS warehouse system enables analysis of bottlenecks in the company. Data from work flows online, thanks to which warehouse staff can assign tasks as needed, and data analysis at a later date will allow better planning of work for the future.

- Advice and work planning. Our WMS software enables cooperation with suppliers and recipients through the electronic exchange of documents, including documents regarding receipt or release of goods. Operators have data that can better plan warehouse operations directly in the system.

- Reduction of error handling costs and complaints. The use of bar codes describing the goods enables verification of operations confirmed by employees on data collectors. The system checks whether the operation carried out on a given batch of goods is justified. Errors related to the delivery of incorrect goods to the customer are significantly reduced.

- Full documentation and batch tracking. The WMS IT system makes it possible to track a batch of goods from acceptance to delivery. Along with the batch, all defined attributes such as expiry date and photographic documentation are tracked. If irregularities are detected at a later stage, the system allows you to verify the origin of a given batch of goods.

- Reduction of paper documentation. The implementation of the WMS system enables a significant reduction of paper documentation. All necessary data related to the handling of goods is saved in electronic form in the IT system. Of course, the software allows you to print documents for the needs of our contractors, it also has a print generator that allows you to tailor them to your needs.

- Warehouse data analysis. Confirmation of each warehouse operation by the operator on data collectors or barcode readers generates a large number of records in the database. Aggregated data is a source of information for all kinds of analyzes that can be generated by a WMS user.

- Easier implementation of new employees in the company. The WMS program guides the user from activity to activity, which significantly reduces the time needed to implement a new employee. The software tells you where and what operation to perform, then verifies its correctness. The employee does not have to be familiar with the distribution of goods in the warehouse, the system will tell you what to do.

- Improving internal processes. The WMS warehouse program also supports internal processes including release and receipt from production. Our software can be integrated with any ERP system, or use our proprietary production management solution. On the one hand, the WMS system can prepare pickings of goods required for production, and on the other hand take ready products to stock.

- Complaints management, laboratory tests, etc. The WMS system manages batches of goods, each of which can be assigned any set of characteristics such as admission to trading. Thanks to this, you can block goods at the warehouse due to complaints, the need to perform tests allowing the goods to be marketed or other types of procedures in the company.

- Reservation and nomination of goods. The program allows you to book goods for specific internal orders and external advice. Goods in stock may be reserved and nominated for export with accuracy to the lot in accordance with the adopted strategy. So you can prepare the necessary transport documents for your vacation.

- Handling entrusted goods. The program allows the identification of goods due to the owner, which allows you to manage the goods entrusted to the warehouse. The system allows you to prepare procedures and rules for managing this type of goods.